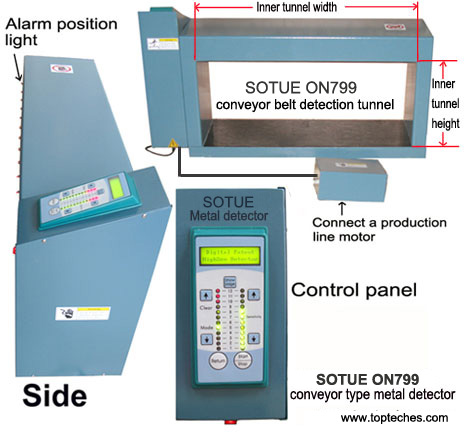

Product

SOTUE ON799 industrial tunnel conveyor type needle detector, tunnel metal detector headON799 industrial tunnel conveyor type needle detector series products adopt the international advanced technology and micro-chip digital signal processing technology and adopt know-how of high sensitivity and intelligentized location display and counter system. It has a very strong anti-interference capability and suits more complex environment use.

ON799 detector products were exported to India, Brazil, South Africa, Italy, Mexico, Vietnam, Australia, South Korea and Turkey etc. to local clients' industrial uses by distributors.

Application:

It can inspect shoes, hats,

non-woven products, high elastic cotton clothing, paper & plastic plates and inspect

sewing products, toys, food products, chemical products, pharmaceutical

products, rubber products, stones, cement, coal, mining materials and so on, it can be installed directly in a production line for safety inspection and can also detect pharmaceutical products and food products packaged by Aluminum foil for safety check.

Technical data:

Detection tunnel width: 350mm, 400mm, 500mm, 600mm,

700mm, 800mm, 900mm, 1000mm, 1100mm, 1300mm, 1500mm, 1600mm, 1800mm and 2100mm

for selection.

Detection tunnel

height Tunnel detection

sensitivity

100mm

FeΦ≥0.8mm

120mm

FeΦ≥0.8mm

150mm

FeΦ≥1.0mm

200mm

FeΦ≥1.2mm

250mm

FeΦ≥1.5 ~ 2.0mm

300mm

FeΦ≥2.0 ~ 2.5mm

350mm

FeΦ≥3.0 ~ 4.0mm

500mm

FeΦ≥3.5 ~ 8.0mm

600mm

FeΦ≥4.0 ~ 10mm

700mm FeΦ≥5.0 ~ 15mm

800mm

FeΦ≥6.0 ~ 20mm

900mm

FeΦ≥7.0 ~ 30mm

1000mm FeΦ≥8.0 ~ 35mm

Feature:

1. ON799 LCD control panel gives you a good operation environment, real time level display and automatic counter function. Automatic inspection function.

2. When it detects a broken needle or a ferrous metal or a magnetic material, its alarm signal can be given out.

3. Designed for universal AC power supply. Optional function: printing reports with a printer.

4. When the broken needle or other ferrous metal or magnetic metal is detected and found, the detector will give out an alarm, and at the same time, the conveyor belt will stop or return automatically. If its alarm is normal, the alarm position LED light on the detector will light up to instruct the object place of a broken needle or other ferrous metal or magnetic metal on the conveyor belt. Twelve level sensitivity adjustment.

5. ON799 detector head can control the startup and stop of your motor on the production line. When the detector detects a metal object on the production line conveyor belt, it will warn, an external alarm position LED light of the detector on the conveyor belt will instruct the approximate location of the metal object under this LED light.

It has the alarm display of multiple LED lights, when a LED light is bright, it can tell you the present location of the metal object on the conveyor belt, thus, a worker is easy to clear the metal object.

6. We adopt a most advanced digital technology to produce it with an exclusive design, it owns the alarm position display lights (As shown above: Alarm Position display LED light photo).

Technical standards:

1. Conform to EN 60950-1: 2006+A11: 2009 electrical product safety international standard. Anti-jamming conforms to EN 50082-1 international standard.

2. Conform to EN 61000-3-2:2006+A2:2009 and EN 61000-3-3: 2008 product safety international standards.

3. Conform to EN61000-6-1:2007 product immunity international standard. Radiation conforms to EN61000-6-3:2007 product emission international standard.