Product

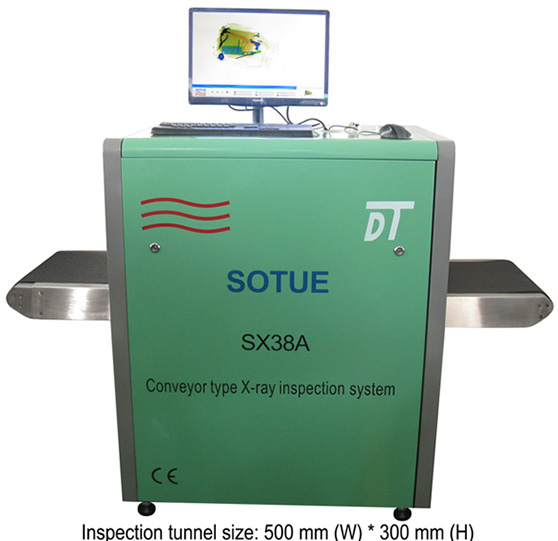

SOTUE SX38A conveyor type x-ray inspection baggage & parcel system

Application:

SOTUE SX38A tunnel conveyor type x-ray inspection baggage & parcel system is used for explosives and suspicious dangerous goods inspection, it can be installed in banks, stadiums, casinos, courts, prisons, embassies, police cars, mosques, churches, checkpoints and so on for security inspection, widely used in stations, banks, stadiums, courts, prisons, mosques, labor camps, detention centers, schools, big speech places, churches, embassies, exhibition, troops, postal parcel inspection & other security departments for security checks and so on.

SX38A system products have been exported to Russia, Nigeria, Libya, Spain, Kuwait, Malaysia, Vietnam, Egypt, Italy, Thailand, India, Italy, Brazil, Morroco, Turkey and Mexico to local customers' uses. We have provided its OEM products for our some customers in Europe, the United States and Japan for many years.

Feature:

1. Use the standards as references when the machine inspects the goods. Monitor: one 19" color monitor, optional: two 19" color monitors and one monitor console. Its operating system is French or English language for your choice.

2. Optional: Network interface, it can connect local area networks and support multi-terminal inspection baggage simultaneously. Optional: the LCD monitor can be folded and 360 degree rotary operation.

3. Safer ray: x-ray under automatic control to avoid the leakage. 4. Turn off or turn on by a key control, its operation is very simple.

5. Image function: can clearly observe and enlarge images. Threat image display: such as guns, knives, bullets, bombs, pistols and so on. Work status display. Image thumbnail display. It can provide outstanding threat detection.

6. Automatic checking and recovery function. Date and time display. Password control. Luggage count. Emergency stop.

Technical data:

Inspection tunnel size: 500 mm (W) × 300 mm (H). Conveyor speed: 0.22 m / s. Conveyor maximum load: 90 Kg. Film safety: for ASA / ISO 1600. Wire resolution: Φ 0.1 mm copper wire. 38 ~ 40 AWG. Storage temperature: -20 ºC to 60 ºC. Relative humidity: +10 to 95% non-condensing. Operating temperature: 0 ºC to 45 ºC.

Power wastage: 500 W (maximum). Noise: < 60 DB. Power supply: 110V ~ 220 VAC (±10%), 50±3Hz. Optional appearance color: Green or silver gray.

Optional: Input conveying length: 1000 mm; exit / output conveying length: 2500 mm.

X-ray generator:

Orientation: vertically upward. Tube current: 0.3 ~ 0.5 mA (adjustable). Anode voltage: 80 KV. Angle: 60 degree. Generator cooling / working periods: sealed oil bath with forced air of 100%. Its penetration power to all metals. Optional: SX38A dual view system.

Image performance system:

X-ray sensor: L type photo-diode array detector, 16 Bit, high resolution 19" LCD color monitor, color quality: 24 Bit real color, edge enhancement: object contour edge is more distinct. Super image enhancement: image details are more distinct. Max. penetration strength display: can increase brightness of dark areas in the image to display an object and low penetration strength display: can increase the contrast to display it distinctly. Brightening / dimming: increase brightness of image / decrease brightness of images. Image recurrence: display previous twenty images and process any one of them.

Image restoration: it restores an image to initial status at the time of stopping the conveyor, and image storage: real time to store any image and process it in the operation status. Zoom: Standard enlargement image up to 32 times.

Standard image storage: 50,000 images, optional: 100,000 images. Installation standard hard disk: 500 GB. Display memory capacity: 2.0 GB. Contrast sensitivity: Min. 24 levels. Image display: Min. 1280 x 1024 bits / pixel and Min. 4096 gray levels. Cycle operation: 100% without warm-up time. Processor CPU: Intel Celeron, optional CPU: ARM Cortex A9.

Technical standards:

1. Conform to EN 60950-1:2006+A2:2013 product safety international standard. 2. Conform to EN 61010-1:2010 product safety international standards.

3. Conform to EN55011:2016 product safety international standard, conform to EN61000-6-2:2005 product immunity international standard.

4. Conform to EN61000-3-2:2014 and EN61000-3-3:2013 product safety international standards.

5. European CE and EMC international security standard certificates. Conform to FAA 3-gun testing standards and NILECJ-0601-00 safety standards. Conform to ECAC international security standard. Conform to U.S. A. Transportation Security Administration (TSA) standard.